Sewage Pump Stations FAQs

What is a sewage pump station and how does it work?

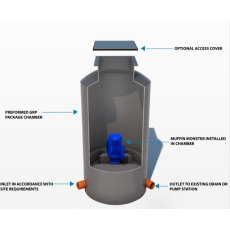

A sewage pump station is a storage chamber incorporating a sewage pump which transfer either the foul or surface water to a local drain, manhole, sewer or soakaway pit.

A pumping station is used where a normal gravity system cannot be, either because there is insufficient fall over a distance, or the common collecting point is lower than the discharge point.

To see our full range of pumping stations click - https://www.tanks-direct.co.uk/waste-water-tanks/sewage-pump-stations/c1011

A sewage pump is a submerged pump that moves sewage solids from one point to another, usually from a septic tank or sewage treatment plant to a percolation area or soakaway pit which is a distance away of uphill. Alternatively, it can be used to pump into a gravity flow sewer mains.

How long can a sewage pump run continuously?

Sewage pumps are typically designed to operate intermittently rather than continuously. The duration a sewage pump can run continuously will vary. Smaller domestic sewage pumps are generally not built for continuous operation and are meant to pump wastewater as needed. Larger, industrial-grade pumps may have the capacity and durability to run continuously for extended periods, but even they may require periodic rest to prevent overheating and wear. Domestic sewage pumps are designed to handle typical household or small-scale sewage flows. If the pump has to handle a sudden surge or an unusually high volume of wastewater, it may not be designed for continuous operation under such conditions.

Continuous operation can lead to heat build-up in the pump's motor and components and overheating can cause damage or reduce the pump's lifespan. Pumps are usually designed with cooling mechanisms, but they may still need breaks to dissipate heat effectively. Regular maintenance can extend a pump's operational duration. Always consult the manufacturer's guidelines and specifications for your specific sewage pump. These guidelines often include recommended operating durations and intervals for rest. Following these recommendations is essential to ensure the pump's longevity and efficient operation.

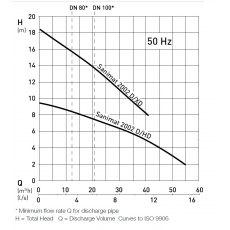

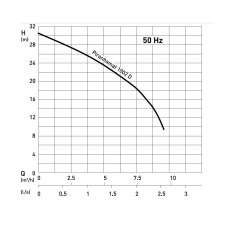

What size pump do I require for my Sewage Pumping Station?

The size of the pump required is down to the rise to main from the tank to the sewer, please call us for further help on this.

How to select the correct pumping station system?

All Klargester pumping stations are suitable for pumping waste water effluent and sewage in accordance with BS 756-2. They are also designed in line with Building Regulations for Foul Drainage.

Your system size will depend on the type of waste you need to manage, your distance from the sewer and the difference in levels.

For expert advice, to help you select the correct system, please contact our specialist team.

The key factors to size your system are as follows:

- Application: domestic, residential or commercial.

- Material application: sewage, effluent or surface water.

- Inlet depth (below ground level).

- Pumping distance and lift.

- Electrical supply.

To see our full range of pumping stations click - https://www.tanks-direct.co.uk/waste-water-tanks/sewage-pump-stations/c1011

How much does it cost to install a sewage pump station?

The first cost to consider is for the sewage pump station itself. And this will vary greatly depending on the specific model you chose. Whether you need a single or double sewage pump station, you’ll find our prices at Tanks Direct are extremely competitive.

Then comes the cost of installation. If you are installing a pump for the first time in a space previously unprepared for installation, the cost will be higher than if you are replacing an existing pump. This is because all the additional preparation required has already been done. The location of your install could also have a bearing on the installation cost. If the site is awkward to get to or a difficult material to dig up, your costs will be higher.

You’ll also want to consider the ongoing maintenance costs of sewage pump stations. Regular servicing is essential to keep your equipment working as well as possible. Sewage pumping stations are subject to wear and tear and require regular servicing to operate effectively. Catching any issues early will minimise the risk of failure and help prevent costly repairs.

How often do sewage pump stations need to be emptied?

It is vitally important that your sewage pump station is regularly serviced and properly maintained. This will improve the day-to-day efficiency of your sewage treatment pump and help improve its lifespan. By inspecting the pump regularly, you can ensure all the components are working correctly

It is advisable to get your tank serviced once a year. Your tank will be emptied and cleaned, with any blockages removed. If any defects are detected during the service, it’s best to get faulty parts replaced as soon as possible. Failure to fix problems quickly can lead to major issues further down the line. For help and advice on how best to maintain your sewage treatment plant, please contact our friendly and knowledgeable team today.

Are sewage pumping stations noisy?

Sewage pumping stations can vary in noise levels, but they generally produce some degree of noise. The noise from a sewage pumping station primarily comes from the mechanical equipment used to pump wastewater, such as pumps, motors, and control systems. These machines can generate a humming, buzzing, or whirring sound, which can be audible depending on several factors. Larger pumps typically produce more noise than smaller ones. Modern stations often incorporate soundproofing materials and construction techniques to help minimise noise pollution. Most sewage pumping stations are designed to operate around the clock, but you may find that noise is more noticeable during quiet times, such as during the night, when ambient noise levels are lower.

Local regulations and community planning may dictate the noise levels allowed for sewage pumping stations. Authorities often set limits to ensure that these facilities do not become a significant source of noise pollution in residential areas.

Do sewage pumping stations smell?

Sewage pumping stations are designed to transport and pump wastewater, which can contain organic matter and sewage, leading to the potential for odours. However, the intensity and prevalence of these odours can vary widely. Well-designed systems incorporate features to minimise odours, such as properly sealed access points and ventilation systems that help disperse or filter out odorous gases. Regular maintenance of these systems, including cleaning and inspection, is crucial to ensure their effectiveness in controlling odours. Smaller domestic sewage pumping stations may generate fewer odours compared to larger, industrial-scale facilities. This is because the volume of wastewater and the concentration of organic matter are typically lower in residential systems. Warm and humid weather can intensify odours, making them more noticeable, and windy conditions can disperse odours and make them less perceptible. If the pumping station is located close to your home or living areas, you may be more likely to detect any odours, especially if there are issues with the station's design, maintenance, or ventilation.

Many local regulations and building codes require domestic sewage pumping stations to incorporate odour control measures to minimise any potential nuisances to nearby residents. These measures may include odour-neutralising chemicals or filters in the ventilation system.

What size tank do I need?

Tanks are sized on the number of people using the system, you should allow 150 litres per person multiplied by the number of people using the property to calculate your 24hr storage capacity.

For commercial properties please contact us, and we can help size this for you.

Do the tanks come with any pre-drilled inlet holes?

No the tanks are supplied without an inlet hole, this is usually drilled on site however we do supply the seal to make the hole water tight and should you require us to drill this for you at the factory, we can offer this also.

Which make of pumps are used in the Sewage Pumping Stations?

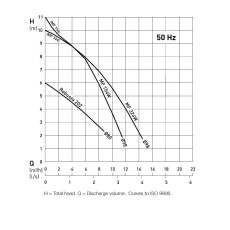

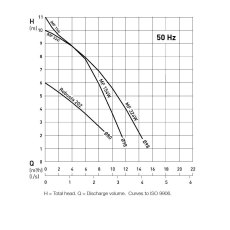

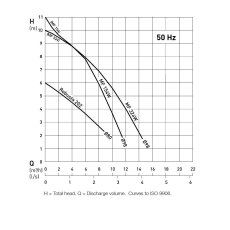

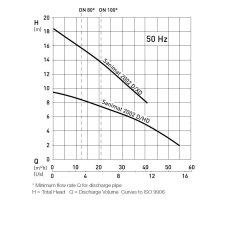

In our 2” vortex range we use Hippo 50 pumps for up to 6m head and Hippo 100 pumps for up to 10m head. In our 2” macerator range we use Semison 125GR pumps, in our 2½” vortex range we use Semison 650 pumps and lastly in our 3” vortex range we use hippo 80-200. Details of which can be found either on our website or a copy can be sent across please call for more information.

Login

Login

.png)