Featured Products

(£538.80 inc VAT)

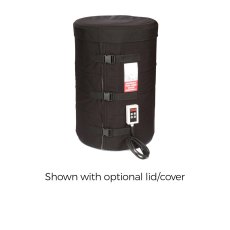

IBC Covers and Heating Jackets

Learn more about IBC containers with our complete IBC guide today.

IBC Covers and Heating Jackets FAQs

What does IBC stand for?

IBC stands for intermediate bulk container. They are large, portable tanks designed to store and transport liquids and semi-liquids. Available in a wide range of capacities from 600 to 1,000 litres, IBC tanks are widely used in various industries to store moderate to large quantities of substances.

Their stackable design allows for efficient use of space, making them perfect for both storage and transportation purposes. Additionally, IBCs often come equipped with pallet bases, making them compatible with forklifts and other handling equipment, easing the process of loading and unloading. IBCs are popular across industries dealing with food and beverages, chemicals, and agriculture, where the safe and efficient storage and movement of substances is paramount.

Always make sure you are familiar with the correct handling procedures and adhere to industry standards. Regular inspections and maintenance of IBCs will help prevent potential leaks or damages, ensuring the substances they hold are secure. When selecting your IBC, consider the materials they are made of and their compatibility with the substances you intend to store or transport.

Can I drink water from an IBC Tank?

IBC tanks are not inherently designed or intended for potable water use. Our IBCs are typically made from materials like high-density polyethylene (HDPE) or metal, and they are primarily used for storing and transporting non-toxic liquids, chemicals, and granulated materials. They are not specifically manufactured to meet the strict requirements for storing and transporting potable water.

While some IBC tanks may have been previously used for food-grade or non-toxic substances, this does not automatically make them suitable for potable water storage. The key concern lies in the potential for contamination or chemical residue from previous contents. Without proper cleaning, sanitisation, and certification, using an IBC tank for potable water can pose health risks.

If you intend to use an IBC tank for storing drinking water, it is essential to verify its suitability and safety. Look for IBC tanks explicitly labelled as "potable" or "food-grade". Alternatively, consider using purpose-built water storage containers to ensure the safety of the water you intend to consume.

How do I safely fill an IBC?

To safely fill an IBC first make sure that the pallet, cage and bottle and valve are suitable for use with the intended product. Ensure that the valve is securely tighten to the inner bottle and that the valve is closed and that the drip cap is secured and tightened. Check that the inside of the bottle is clean. When hot filling product do not exceed 65°C. When bottom filling make sure that the vents are functioning correctly or open the top cap. Do not over fill the IBC. After filling, if the product has a UN number, ensure that the lid seal is correctly positioned and tighten the screw cap to 70-80 Newton/Meters.

How do I transport an IBC safely?

Do not lift IBCs from the top frame. Ensure that the fork truck tines are fully inserted under the IBC before lifting. Ensure that the vehicle floor is in good condition and free of all nails etc. that could puncture the IBC. Always transport IBCs with the correct labelling attached to the ID Plate.

Always secure IBCs to prevent possible movement during transit.

IBC adaptors, which one do I require?

If you would like to attach a garden hose to your IBC- HFUD/2063 would be the adaptor required. Warm the hose to help in pushing the hose onto the adaptors barb, if possible raise the IBC (on wooden pallets) to assist with gravity flow

However if a 2 inch male BSP is required then the 016136 + 1069497 would be recommended. For those who wish to attach other items to the IBC valve, this adaptor turns the valve’s buttress thread into a female 2 inch BSP fitting more common here in the UK

If a 1 inch Male BSP is what you are after then the 31PB24 is the right choice, however if you require a 1” female BSP then 31PN15C is he right adaptor.

If you wish to fit a 1” Male or 1” Female BSP (as mentioned above) - 31PB24 or 31PN15C to an IBC then a 016136 & 1069497 is required.

Can the IBC's (intermediate bulk containers) be stacked?

Yes, depending on the pallet type, our IBCs can be stacked as follows whether empty or full:

MX IBCs - with metal or plastic pallets - Up to 4 High (with a maximum SG of 1.6)

SX IBCs - with metal pallets - Up to 4 High (with a maximum SG of 1.6)

LX IBCs - with wooden or plastic pallets - Up to 3 High (with a maximum SG of 1.4)

How long do IBC tanks last?

The lifespan of IBC tanks can vary depending on several factors. The duration of their functionality will be influenced by the materials they are made from, the quality of construction, and how well they are maintained. Generally, IBC tanks made from high-quality materials like stainless steel or robust plastics such as HDPE can last anywhere from 5 to 20 years or more with proper care.

To extend the longevity of your IBC tank, you should implement regular inspections and maintenance routines. Check for signs of wear, corrosion, or damage, and address any issues promptly. Keep the tanks clean and free from residue, especially if they have been used to store chemicals or other substances. Additionally, store the IBC tanks in a suitable environment, away from extreme temperatures or harsh weather conditions that could deteriorate the materials over time.

When using IBC tanks for storing liquids, it's essential to follow the manufacturer's guidelines and ensure they are not exposed to conditions that could compromise their structural integrity. Regularly assess the condition of the seals and closures to prevent leaks and spills. By taking a proactive approach to maintenance and adhering to safety protocols, you can maximise the lifespan of your IBC tank and get the most out of your investment.

Login

Login

.png)