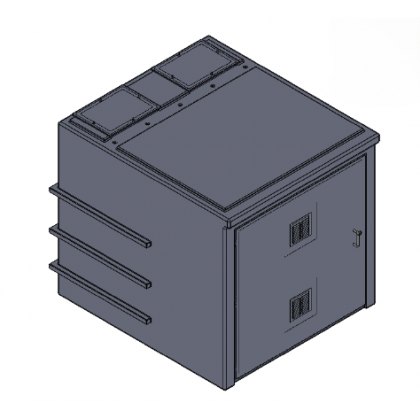

3000 Litre GRP Pump Enclosure with built in tank and 80L/min single pump 9000.3000

Product Ref: CUCOMP.9000.3000.SP

Custom Delivery Required

Delivery price on application.

Dimensions

|

Product Code |

CUCOMP.9000.3000 |

|

External Dimensions (mm) |

3192 x 2192 x 1618 High |

|

Wet Compartment (mm) |

1000 x 2000 x 1500 |

|

Pump Compartment (mm) |

1970 x 2000 x 1500 |

|

Nominal Capacity (Litres) |

3000 |

|

Door Opening (S=Single, D=Double) |

D = 1665 x 1300 |

|

Air Gap |

AG |

Product Description

3000 Litre GRP Pump Enclosure with built in tank and 80L/min single pump

The unit is designed as a single piece item with an internal dividing wall at full height. One internal section being the wet compartment for the stored water, which is accessed via a lid mounted lockable man way. Beyond the internal dividing wall is the dry side where the booster set is to be positioned. The internal dividing wall has the inlet and outlet connection within it, the overflow, warning pipe and screened spill over weir terminate through the wet side wall to the outside and do not therefore normally require any additional pipework. The dry side is accessed by a large 1600 x 1600 mm hinged and lockable door, which is fitted with louvred vents to ensure adequate ventilation.

If chosen with the Foundation Skid, the whole unit is mounted and fixed to a fully welded galvanised steel skid, which allows offloading and movement on site by fork lift struck. The principle is to provide the unit to the booster set manufacturer, where the booster and associated electrical equipment can be fitted. The completed unit can then be delivered to site where once positioned it requires the simple connection of the mains pipework, outlet pipework to the services, and electrical supply, making it a 'plug and play' unit requiring minimal on-site installation.

All units are fitted with the following:

- 1 No 42 mm screened lid vent

- 1 No single 1550 x 1550 mm door to the end face of the pump compartment

- 1 No lockable access man way fitted to the roof of the wet compartment where fitted.

- 1 No EPDM mat to the floor of the pump compartment

- Single Pump - 80L/min as standard however other options available

- A fully encapsulated ply base.

Units do not include electrical components, wiring, pump sets, control equipment, connections of any kind or internal pipework.

Units not fitted with a galvanised steel skid are suitable for positioning onto a structural pad only, which should be flat, level and continuous and be +/- 2 mm over the surface area.

Please note, when the galvanised skid option is added the external height increases by 210 mm.

**Cat 5 (AB and AG) supplied loose

AG Air gap

IP22-AG-SL

- 22 mm (3/4") screened lid vent

- 22 mm equilibrium float valve c/w Float

- 35 mm (1 1/4") screened overflow

- 22 mm (3/4") screened warning pipe

IP28-AG-SL

- 42 mm (1 1/2") screened lid vent

- 28 mm equilibrium float valve

- 42 mm (1 1/2") screened overflow

- 22 mm (3/4") screened warning pipe

IP35-AG-SL

- 42 mm (1 1/2") screened lid vent

- 35 mm equilibrium float valve

- 50 mm (2") screened overflow

- 22 mm (3/4") screened warning pipe

IP42-AG-SL

- 42 mm (1 1/2") screened lid vent

- 42 mm equilibrium float valve

- 67 mm (2 1/2") screened overflow

- 22 mm (3/4") screened warning pipe

IP50-AG-SL

- 42 mm (1 1/2") screened lid vent

- 50 mm equilibrium float valve

- 80 mm (3") screened overflow

- 22 mm (3/4") screened warning pipe

AB Air gap

IP22-AB-SL

- 22 mm (3/4") screened lid vent

- 22 mm equilibrium float valve c/w drop arm and float

- 35 mm (1 1/4") screened overflow

- 22 mm (3/4") screened warning pipe

IP28-AB-SL

- 22 mm (3/4") screened lid vent

- 28 mm equilibrium float valve c/w drop arm and float

- 42 mm (1 1/2") screened overflow

- 22 mm (3/4") screened warning pipe

IP35-AB-SL

- 22 mm (3/4") screened lid vent

- 35 mm equilibrium float valve c/w drop arm and float

- 50 mm (2") screened overflow

- 22 mm (3/4") screened warning pipe

IP42-AB-SL

- 22 mm (3/4") screened lid vent

- 42 mm equilibrium float valve c/w drop arm and float

- 67 mm (2 1/2") screened overflow

- 22 mm (3/4") screened warning pipe

IP50-AB-SL

- 22 mm (3/4") screened lid vent

- 50 mm equilibrium float valve c/w drop arm and float

- 80 mm (3") screened overflow

- 22 mm (3/4") screened warning pipe

Delivery

All our GRP tanks are for delivery by customer offload. This entails the customer to acquire the right manpower and/or machinery to help unload the tank/s from the delivery vehicle.

If you require assistance with offloading, we may be able to offer a tail lift (lowers the tank to the ground) or HIAB (lorry with a mounted crane to winch the tank off the delivery vehicle). Please contact us if this is required for delivery.

**Images are for Illustration purposes only

Product Details

- Product Code: PW

- Colour: Grey

- Customer Offloading: Customer Offloading

- Material: GRP

- Potable: Potable

- Stock tank: Made to Order, Non Returnable Product

- Tank Use: Above Ground

- WRAS: WRAS Approved Parts

Delivery

Our shipping costs cover most of the UK - however, parts of England, Scottish Highlands and Islands including areas north of the Glasgow / Edinburgh border, Isle of Wight, Channel Islands, Isle of Man, Anglesey, Western Isles, Shetland Islands, Orkney Islands, Isles of Scilly, Northern Ireland and the Republic of Ireland may cost more.

Please call before ordering if the delivery postcode is listed below. There may be additional shipping costs. AB, BT, CA, CT, DD, DG, EH, FK, G, GY, IM, IV, JE, KA, KW, KY, LD, LL, ML, PA, PH, PO 30-41 (Isle of Wight), SA, SY, TD, TN, TR, ZE Southern Ireland

Our lead times should only be used as a guide and are subject to change.

Offloading

Unless a hi-ab delivery has been booked at additional cost, it is the customer's responsibility to offload with suitable equipment on the day of delivery and a failed delivery may result in additional charges.

We recommend installers and/or plant hire & materials to install such as excavators, aggregates etc are not booked until you are in receipt of the goods. Tanks Direct cannot be held responsible for costs incurred due to unforeseen delays, please see our terms for more details.

HIAB

HIAB delivery will be required if you need the tank offloaded from the delivery vehicle. The driver will unload the tank from the vehicle to ground level, however this service is not to place the tank in situ, this will need to be arranged separately.

If you have any questions regarding your delivery, please contact the Sales Team on 01643 703358.

Returns Information

Please note - Certain items may not be returnable, for example those made to order or for sanitary reasons. Please check the product page for more information.

Customers may return items within 14 calendar days (as per our Terms & Conditions) - refer to section 7. **

All Items must be returned unused, refunds cannot be issued for used or previously installed items.

Please be aware that returning a tank can be complicated and expensive, so please check that you are ordering the correct item (we suggest checking the dimensions very carefully).

If you wish to return goods, please complete the form on this page to provide further information.

Once your request is approved, a valid Returns Authorisation Number (RAN) will be issued to initiate the returns process along with information on how & where to return your order along with any costs involved.

Please DO NOT return any goods without this authorisation. Goods cannot be accepted without this.

Returns are not accepted at our Minehead Office, please wait until we contact you before returning any goods.

Login

Login.png)