Kingspan Klargester

With over 65 years’ experience, Kingspan Klargester is one of the world's leading manufacturers of wastewater treatment systems. With an international reputation specialising in the manufacture of packaged pollution control products, Klargester has developed a range of innovative products, revolutionising methods of dealing with the treatment of sewage on sites where mains drainage is not available.

Our extensive range of Klargester products include sewage treatment plants, septic tanks, cesspools, pumping stations, fuel and oil separators and grease traps.

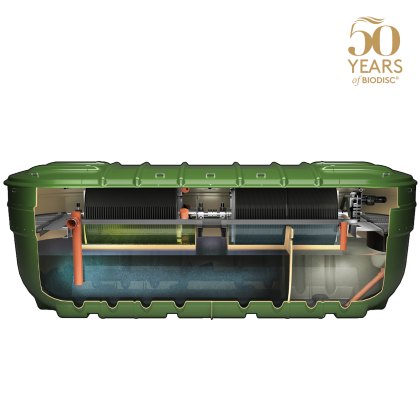

Klargester BioDisc

In 2024, Tanks Direct is delighted to celebrate 50 Years of Excellence for the market leading Klargester domestic and commercial BioDisc sewage treatment plant. The Klargester range of packaged sewage treatment plants are fully compliant, highly efficient and economical to operate. Klargester treatment plants are designed with efficiency in mind, using tried and tested technology to ensure consistently high effluent quality. The BioDisc sewage treatment plant is a unit that offers optimal performance at a low running cost, whilst still complying to the highest environmental standards. Ideal for locations where discharge to sub-surface irrigation, a suitable watercourse or where a septic tank will not meet the required standards. Whether you’re looking for a system to serve up to 6 people, 9 people, 12 or 18, we have the BioDisc sewage treatment plant you’ll need. Beyond that, the commercial BioDisc range for larger applications extends to meet requirements from 25 up to 300 people.

Klargester BioAir

A new cost-effective choice for your wastewater treatment solution, the Klargester BioAir sewage treatment plant, uses aerated technology to deliver a high level of water discharge quality. Economically priced, with low level visibility and suitable for installation in traffic areas, the Klargester BioAir system offers low running costs, with the kind of high performance you would expect from any Klargester product.

Replacing the well-respected Klargester BioFicient treatment plant, the new Klargester BioAir utilises no plastic media and therefore serves to support our commitment towards our Planet Passionate objectives, by reducing plastic use.

And if you currently have a Klargester BioFicient, then no need to worry as we continue to support your requirements with our full range of Kingspan Maintenance and Service Plans and BioFicient spare parts.

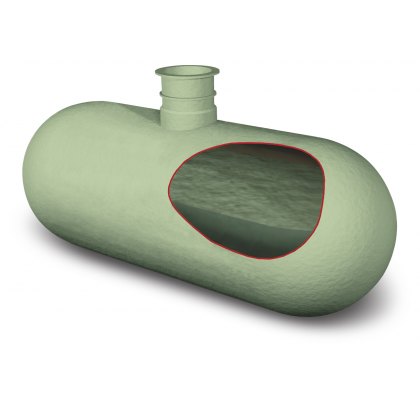

Klargester Septic Tanks

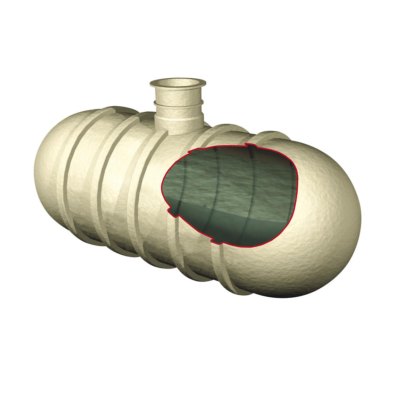

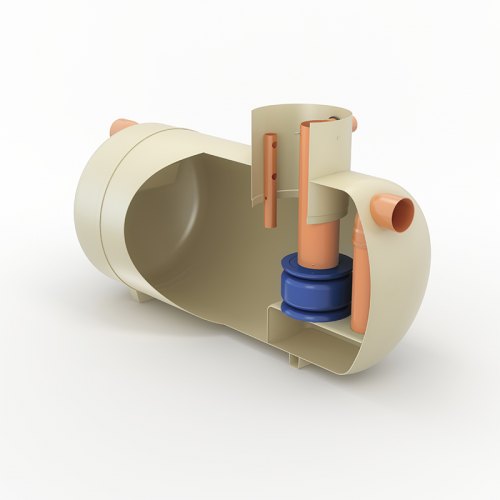

Septic tanks are a traditional solution to sewage disposal needs. The Klargester septic tank range includes options for domestic and commercial dwellings without access to mains drainage. Offering the Alpha range which is bulb/onion shape, the more traditional choice or the shallow dig Sigma and Gamma ranges, which save on excavation costs, making it the ideal choice if price and space is an issue.

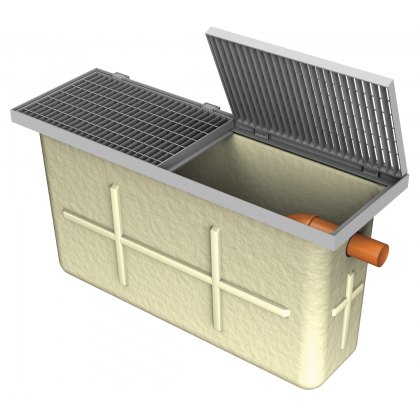

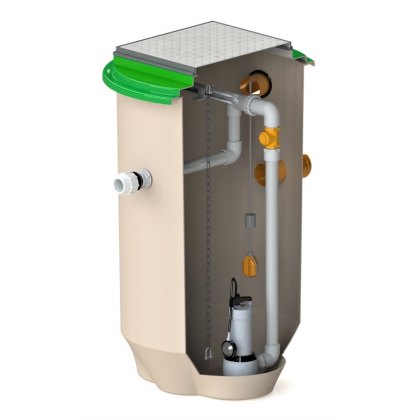

Klargester Pumping Stations

Manufactured from robust GRP, Klargester pumping stations are designed as a single piece chamber, ready to install with no man entry required. Supplied with single or twin pump options, Klargester pumping stations can be provided to meet domestic and commercial requirements and are suitable for sewage, surface water and effluent applications. They are also appropriate where 24 hour storage requirements need to be maintained.

Still unsure why you should choose Kingspan Klargester?

We offer a large range of Klargester spare parts, if you are ever in need of replacement parts.

Frequently Asked Questions

Brands

Klargester

Who or what is Klargester?

Kingspan Klargester is one of the world's leading manufacturers of wastewater treatment systems, with over 65 years experience, within the industry, With a global reputation specialising in the manufacture of packaged pollution control products, Klargester has developed a range of innovative products, revolutionising methods of dealing with the treatment of sewage on sites where mains drainage is not available.

Their extensive range of Klargester products include Sewage Treatment plants, septic tanks, Cesspools, fuel and oil separators and grease traps.

How often should I empty my Klargester tank?

Sludge builds up in septic tanks and it must be regularly removed to keep your Klargester tank working for as long possible. Tanks that are poorly maintained will need repairing or replacing sooner and could experience issues like bad smells, blocked pipes, cracked and blocked pipes, and failed motors and pumps. You may also notice soggy ground and pools of water forming around the drainage point, a sign that the effluent is not draining from the house quickly enough, are all indications that your Klargester septic tank is not coping.

You should get the sludge that builds up in your septic tank removed, a process called ‘desludging’ before it exceeds the maximum capacity. We recommend your Klargester tank should be desludged a minimum once a year and always ensure that the company you use to remove the sludge is a registered waste carrier.

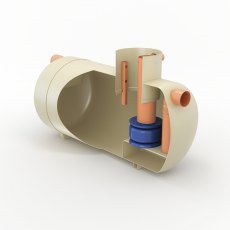

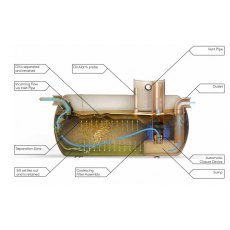

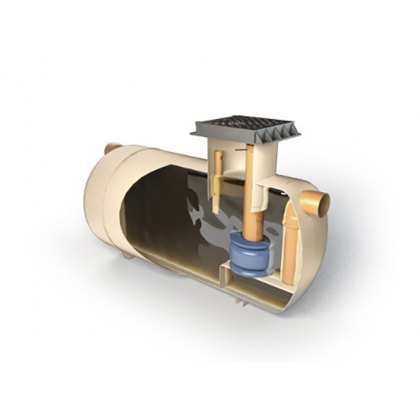

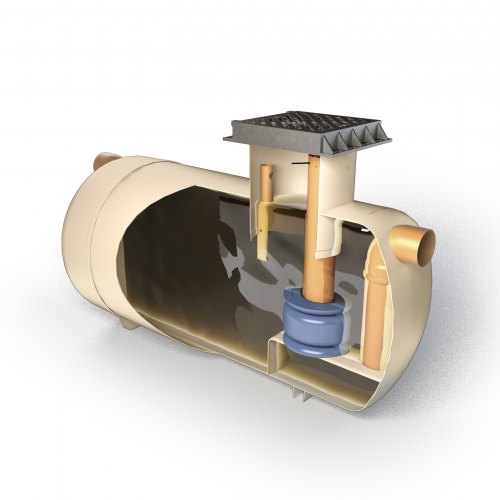

How does a BioDisc work?

The BioDisc uses a Rotating Biological Contractor (RBC) system which includes three stages to treat waste water. After the water has passed through a primary settlement tank, where heavy solids settle to form a sludge in the bottom of the tank, it moves into the Biozone for breaking down by microorganisms on the RBC. Suspended solids return to the primary settlement zone, and the liquor is transferred to the second stage Biozone for further treatment. Any remaining solids are settled out in the final settlement tank, leaving the remaining effluent clean enough to be discharged into a watercourse.

Do I need planning permission for a Klargester septic tank?

If you are planning to install a new septic tank, you will need planning permission from the local authority. This applies to residential sites, as well as commercial. If you already have an existing septic tank installed, either at home or as part of your business premises, you won’t need planning permission if you are simply intending to replace it. It doesn’t matter how old your existing septic tank system is — you can have it upgraded or replaced entirely, and you won’t require planning permission from your local authority.

How close can a septic tank be to a dwelling?

Septic tanks sit underground and release wastewater slowly into the surrounding environment. For this reason, they must be installed at least seven metres away from a house or ‘habitable property’ and at least 50 metres away from any water sources. It is very important that you comply with all regulations for both health and safety and environmental reasons. You will also need to check if you need a permit, which usually depends on where you intend to release your wastewater.

How much does it typically cost to install a septic tank in the UK?

There are lots of factors that might affect the cost of replacing or installing a new septic tank. Costs can be high depending on where you live, the type of ground you’re installing the septic tank into, and many other factors. After you have selected and paid for your chosen septic tank, the installation cost could be anywhere from £2,000 to £4,000.

With replacement septic tanks, a lot of the infrastructure like pipework, plumbing and foundations will already be there – helping to keep costs down. Remember, though, that you’ll need to empty out all the sludge that’s built up over time from the old tank and rinse it until it’s safe enough to remove to the waste disposal site. New septic tank installations will require new plumbing, pipework, and foundations, as well as somewhere to dispose of the soil or ground dug up. Installing your septic tank could take anywhere from three to seven days, all which will be factored into the price.

How does a Klargester Septic tank work?

A Klargester septic tank disposes of the sewage and wastewater from your property. It collects the wastewater from your property and separates the solids from the liquids, and then any leftover effluent is discharged into a drainage field or soakaway.

There are three different types of septic tanks, each with their own benefits and suitability to different properties and individual requirements.

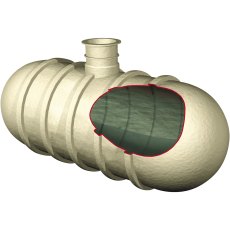

The Alpha Klargester septic tank

One of the most popular Klargester septic tanks, the Alpha tank is light, watertight, and particularly strong. Thanks to its shape the tank is easy to handle and install and has a subtle visual impact that many people find desirable.

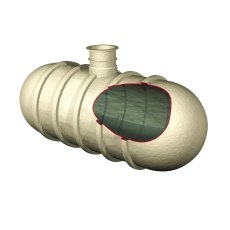

The Sigma Klargester septic tank

Light, robust, and chemically resistant, the Sigma Klargester septic tank is one of Klargester’s easiest tanks to install. The reduced excavation costs make the Sigma Klargester a popular choice.

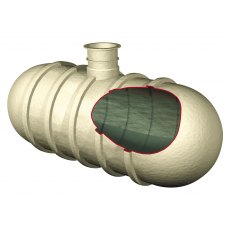

Gamma Klargester septic tanks

If you’re looking for a more environmentally friendly choice, look no further than the Gamma Klargester septic tank. It is easy to install, durable, strong and lightweight.

Login

Login

.png)