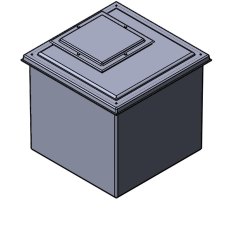

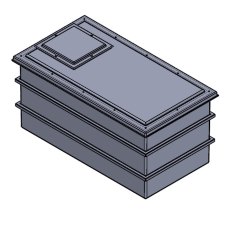

Uninsulated GRP break Tanks FAQs

What is a GRP tank?

A GRP tank is a tank made with Glass Reinforced Plastic (GRP). They are renowned for their remarkable strength-to-weight ratio, achieved through a construction process that weaves tiny glass fibres into a web-like structure, before being fused with a special resin and catalyst. This creates a rock-solid composite material that can handle serious pressure and bumps. GRP tanks are also great at resisting corrosion. Unlike old metal tanks that rust, GRP naturally resists most chemicals and weather elements. Unlike some plastics that degrade under constant sun exposure, GRP tanks boast exceptional UV resistance, making them ideal for outdoor storage applications without worrying about cracks or weakening.

While GRP tanks excel at water storage, their applications extend far beyond that. They can be used for safe containment of various chemicals, fuels, and even food products due to their non-contaminating properties. At Tanks Direct, we only stock the highest quality GRP tanks that are built to stand the test of time. Unlike some plastic tanks that get brittle over time, our GRP tanks stay strong and reliable for years. Plus, their smooth, non-porous surface makes cleaning and maintenance a breeze.

Fully WRAS approved.

Benefits of GRP over steel or plastic

Most GRP tanks are supplied fully pre-insulated with PU foam fully encapsulated within the GRP laminate, GRP tanks come in a wide range of standard sizes and can also be supplied bespoke to suit your specific size and configuration requirements.

Whats the difference between an AB or AG air gap tank?

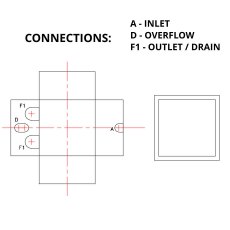

An AG type airgap provides mains water protection from fluid category 1-4 with standard lid arrangement for an inlet float valve fitted in the body of the tank, and an AB type air gap, also known as category 5, is when a raised float valve housing is fitted with a spill over weir in addition to the overflow in the body of the tank.

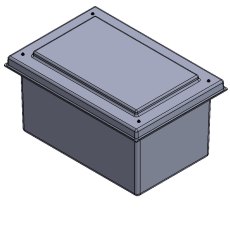

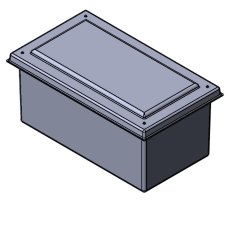

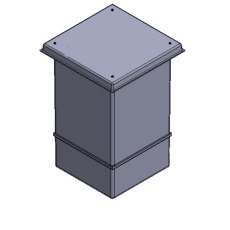

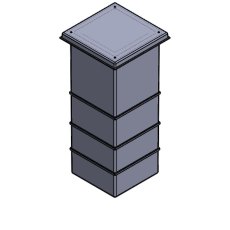

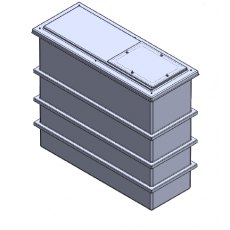

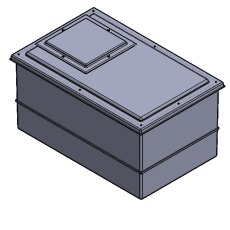

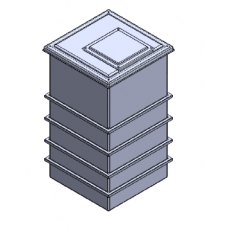

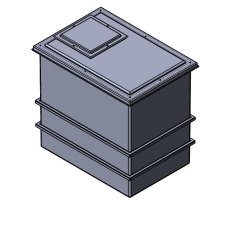

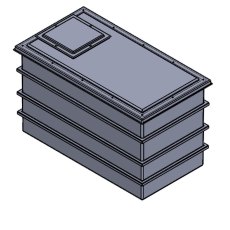

When is a 1 piece, 2 piece or sectional tank used?

1 & 2 piece tanks are available from 90 to 12,000 litres, sectional tanks can be supplied from 125 to 2,000,000 litres. Usually where access permits a 1 piece can be used without any assembly needed, if access is restricted a 2 piece tank can be installed and the top and bottom halved bolted together on site. Sectional tanks are for where access restrictions or other conditions deny the installation of one and two piece tanks. They comprise of individual bolt-up panels which are assembled on site.

Sizing a float valve for my GRP tank, which one would I need?

A float valve will usually be sized to suit your incoming mains water supply, so if you have a 25 mm incoming mains you will need a 1” float valve. If we supply the float valve with your tank we will size and supply the overflow to suit this.

What is a WRAS tank and is it compulsory?

The Water Regulation Advisory Scheme sets legal requirements for the design, installation, operation and maintenance of plumbing systems, water fittings and water-using appliances. These Regulations and Bye laws apply in all types of premises supplied, or to be supplied with water by a water company. All of our insulated GRP tanks are fully WRAS approved, so can be connected to a mains cold water supply. These regulations do not apply where a property uses a private water supply and does not have a supply of water from a water company.

There are lots of optional extras on the GRP tanks, what are they and are they required?

Our GRP tanks are usually supplied without any connections, as many customers supply and fit their own. However we can supply a comprehensive range of items including inlet float valves, outlet connections and other fittings to suit your individual application. Please contact us to discuss or request a quote for your requirements.

Do you supply pumps with the GRP tanks?

If you require a booster pump, you must fit a break tank to the incoming mains water supply to connect to the pump set. Our GRP tanks are ideal for break tanks. We can supply a wide range of booster sets where a break tank is needed.

Do you offer a clean & disinfection of tanks which have been previously been purchased?

Yes, we can supply a quote for cleaning existing tanks. We can also arrange to clean and disinfect newly installed tanks as part of the supply and assembly service on all new 1, 2 & sectional tanks.

Benefits of professional onsite assembly of Sectional Water Storage Tanks

The benefits of purchasing onsite assembly for your sectional water storage tank, you will have experienced engineers onsite to assemble your water storage tank, All engineers have valid CSCS cards , asbestos awareness training and certification , confined space training and certification.

We have a national coverage service assembling tanks day in day out & engineers are fully experienced in their field of works

You should have peace of mind that all engineers are solely employed by the tank manufacturer directly and are educated to understand all water regulations in accordance with WRAS and the current water regulations guide & will ensure that your tank installation is meeting all current regulations to save any potential implications post install.

Our engineers will check the whole area including the base to make sure that the environment meets all required criteria to carry out a successful & safe assembly. Engineers will also drill & fit any connections purchased with the tank providing a representative onsite can determine the location that these connections should be fitted.

Not only will you take away the peace of mind that your tank has been assembled to a professional standard, you will also have a fully guaranteed tank which will cover all components & the assembly itself for a full 12 month period from the date of assembly.

By selecting the onsite assembly option, you must agree & ensure that all tank components will be taken to the area where the tank is to be assembled prior to the engineers arrival to site.

Once the assembly is complete, engineers will ask your nominated site contact to check the assembly & sign to confirm that they are happy with the works. Your site contact will be left with a copy of this paperwork which will advise that you must fill the 10 days of the assembly & send evidence of this over to a specific email address, this is very important to do this in order to validate your warranty.

How long do GRP Tanks usually last?

We understand you want a tank that can withstand the elements and years of use without succumbing to wear and tear. That’s why we offer a wide range of GRP tanks, renowned for their exceptional lifespan. Their impressive durability stems from their unique construction. Unlike traditional metal tanks that can rust, GRP tanks have a durable composite structure. Glass fibres, woven into a strong internal network, are infused with a specially formulated resin and catalyst. This creates a remarkably resilient material that resists pressure, impact, and the detrimental effects of time.

While a precise lifespan can vary depending on specific usage and environmental factors, GRP tanks are generally estimated to last for a minimum of 25 years. Many GRP tanks, with proper care and maintenance, can even exceed that timeframe, providing dependable service for well over three decades. This extended lifespan makes GRP tanks a cost-effective choice in the long run, eliminating the need for frequent replacements.

At Tanks Direct, we source our GRP tanks from reputable manufacturers who prioritise exceptional craftsmanship. These tanks are designed and built to endure the demands of everyday use. The smooth, non-porous surface of GRP tanks simplifies cleaning and maintenance, further contributing to their extended lifespan.

What are the main benefits of a GRP Tank?

GRP tanks are renowned for their unmatched strength-to-weight ratio. This advantageous characteristic is achieved through a unique construction process. Glass fibres are woven into a web-like structure, creating a framework that is then infused with a specially formulated resin and catalyst. This allows GRP tanks to withstand significant pressure and forceful impacts, ensuring the safe and secure containment of liquids. While they excel at water storage, GRP tanks boast non-contaminating properties, making them ideal for the safe containment of various chemicals, fuels, and even food products.

Unlike conventional metal tanks that are susceptible to rust and deterioration over time, GRP tanks are resilient against a multitude of chemicals and the harsh effects of weather. This inherent resistance allows for the safe storage of a wide variety of substances, including rainwater for your garden to potent industrial liquids used in various manufacturing processes. You can rest assured that your GRP tank will maintain its structural integrity for years to come.

While plastic tanks tend to become brittle over time, GRP tanks retain their remarkable strength and structural integrity for decades – plus the smooth, non-porous surface simplifies the cleaning and maintenance process. This minimises downtime and ensures optimal functionality over an extended lifespan.

What is the differences between a GRP Water Tank and a MDPE tank?

GRP (Glass Reinforced Plastic) and MDPE (Medium-Density Polyethylene) tanks are both popular options, but they have key differences. GRP tanks are known for their impressive strength-to-weight ratio. This strength comes from its unique build. Glass fibres are woven into a web-like structure, then fused with a special resin for a rock-solid composite. This makes GRP tanks ideal for long-term use, lasting well over 25 years with proper care. MDPE tanks, on the other hand, are typically lighter than GRP. However, they might not be as strong, especially for larger sizes that need extra support to avoid bending. While MDPE tanks offer good chemical resistance, it might not be suitable for all substances compared to GRP's exceptional resistance. GRP tanks can be moulded into various shapes and sizes to fit your needs, and even coloured for aesthetics or safety regulations. MDPE tanks, however, are generally limited in shapes and colour options. Both GRP and MDPE tanks are easy to clean due to their smooth surfaces. However, GRP's longer lifespan makes it a more cost-effective option in the long run, even though it has a higher initial price tag compared to MDPE. MDPE tanks, while affordable upfront, might need replacement sooner due to their potential for UV degradation and shorter lifespan.